Proneem is the specialist of micro-encapsulation technology. Its first technology : PRONEEM, based on the encapsulation of natural neem oil is patented. This patent has permitted to beget numerous innovative and high-performance range of technologies.

What is microencapsulation ?

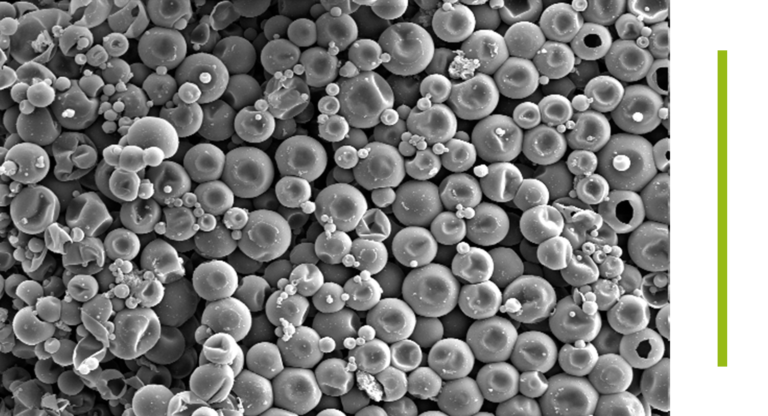

By encapsulating active ingredients in tiny particles, we can bring new superpowers to fabrics, enhancing their performance and functionality. Microencapsulation is a process in chemistry where tiny particles of one substance (called the “core”) are encapsulated by a shell made of another substance. The resulting microcapsules are typically less than 1mm in diameter and can be designed to have a specific release profile for the core material. The process of microencapsulation can be achieved through various techniques, including spray-drying, coacervation, and emulsion-solvent evaporation. During the process, the core material is mixed with the shell material and subjected to specific conditions, such as heat or pressure, to form the microcapsules.

How it it applied on textile ?

At the end of the production, the micro-capsules containing actives are in liquid form. This liquid is applied on textile during the finishing process when the fabric is treated in order to give it various characteristics : color, pattern … or features regarding Proneem technologies. Once the fabric is then treated with the microcapsule solution, either by padding or spraying, and the solvent is evaporated, leaving the microcapsules embedded in the fibers of the fabric. The fabric can be further processed by washing or finishing to improve the durability of the microcapsules.

HOW ARE ACTIVES LIBERATED?

When the fabric endures a friction or rubbing, some micro capsules are going to break and release the actives they contain. Then, these actives are going to give textile the chosen feature : anti-dust mite, refreshing, olfactory … Microcapsules and the actives they contain stay within the weave of the textile until they endure or friction hanks to the innovative process of microencapsulation. The release of active is progressive and consistent.

One example of microencapsulation application in textiles is the use of microcapsules to provide fragrance to fabrics. Fragrance microcapsules can be added to textiles, such as clothing or bed linens, to create long-lasting and pleasant-smelling fabrics. When the fabric is rubbed or agitated, the microcapsules break open, releasing the fragrance.

Une multitude de fonctionnalités performantes qui apportent une valeur ajoutée ou produit fini

Des fonctionnalités durables dans le temps

Une meilleure image du produit par l’utilisation d’actifs d’origine 100% naturelle

Designed to destroy or repel harmful organisms or

render them harmless

To increase the body’s performance of the body and reveal challenges

To improve comfort and provide sensory experiences experiences in everyday life